Gorilla-proof shipping crate for your mirror

After spending the winter fussing over the figure of your latest mirror, you start to dread handing it over to the brown clowns to get it coated.

You remember the bootprints and bashed-in corners on the crate your blank arrived in, and want to give your precious jewel a fighting chance.

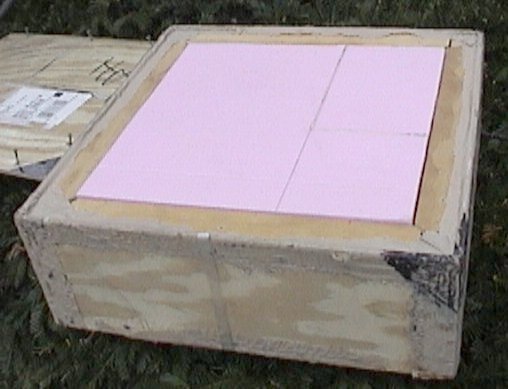

Here's my way-overkill crate, ready to screw down the lid.

I reinforced the corners and long sides with hot-melt-glued strips of ripstop nylon cut from an old tent.

Everything is glued and screwed together except the top lid, which is only screwed (for obvious reasons).

A length of shipping tape on the four long edges of the square top prevents splinters.

It's built from 1/4" plywood with eight 1 x 2 glue blocks along the long sides and four 2 x 2 blocks on the short vertical corners

Mark one corner with magic marker so the coater will be able to get the screws to fit again.

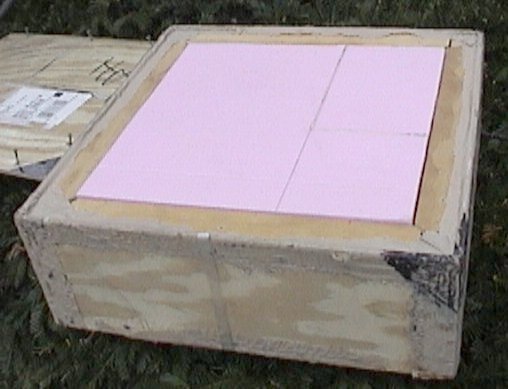

Here's the crate with the lid off, showing the square top sheet of 1" hard styrofoam insulating board.

Here's the crate with the top sheet of styrofoam removed.

After the top sheet, you have to make the inserts in sections so it can reach the walls but still be disassembled.

Cut a piece of cardboard to the diameter of your mirror, then cover the polished face with surgical cotton and masking-tape the cardboard disk over it.

This shows the disk in it's round cutout, cotton-side up (no mirror)

One corner of styrofoam is removed here, showing the bottom-face styrofoam square and the 2x2 vertical corner brace

This crate was just used to ship the 12.5" BVC mirror from my leftover scope.

Leftover scope

It survived the trip with no damage at all.

I used the same construction earlier on the crate for my 20 inch mirror, adding full-length nylon reinforcing this time.

For larger mirrors, use 1/2" or thicker plywood.

Design it to be able to survive being thrown off the dock to the concrete several times, and you won't be disappointed.

UPS will charge more for a wood crate than for cardboard - seems only fair - I wouldn't want to get splinters or a bad back from my job either.

Be considerate and tape or hot-melt glue any edge or corner that would be hard on the guys that handle it.

Back to home page